Do you have a product or an ensemble that you need help with? The solution to your problems is just a phone call away. We’ll save you time and solve the challenges and problems with turnkey service. All services under one roof.

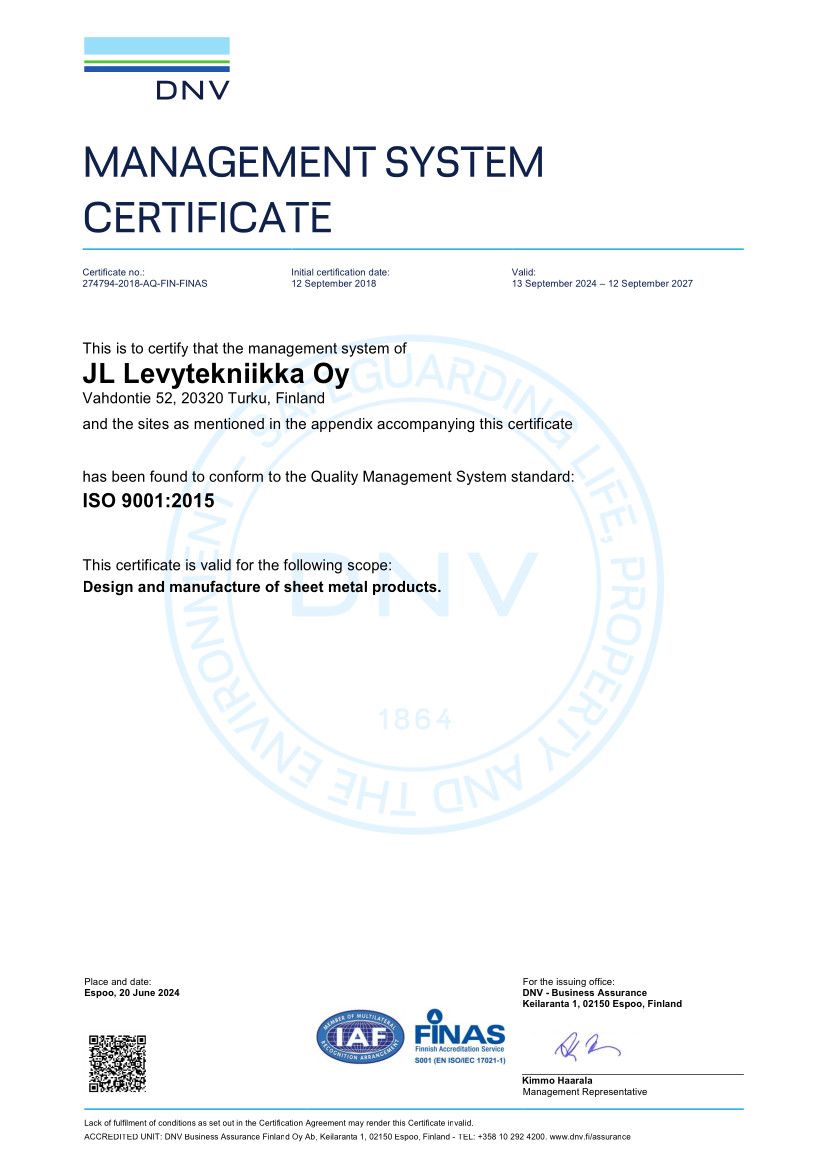

We are an ISO 9001: 2015 and ISO 14001: 2015 certified manufacturer of sheet metal products. Our staff consists around 33 people.

In addition to design and manufacturing, we provide electrolytic surface treatments, painting, prints, and machining through our subcontractors.

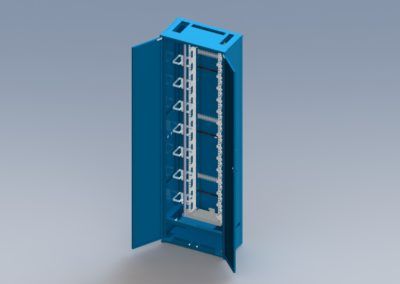

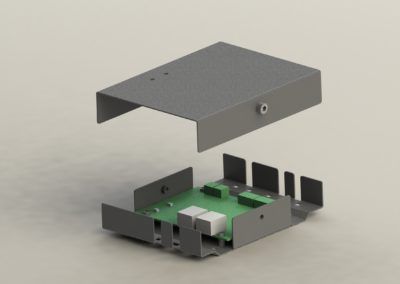

We also do mechanical assembly work for our customers, from well-equipped enclosure structures to well-designed equipment cabinets.

By providing the most refined solutions, tailored to the customer’s needs, we are able to save our customers time and resources.

We are able to produce small prototypes quickly and cost-effectively, as well as consult and provide expert service to our clients.

We supply products to companies in the electronics, vehicle- and construction industries, more than 90% of our products are exported indirectly.

Ten reasons to choose JL Levytekniikka Oy as a partner

- Assurance

- Speed

- Good Service

- In-house mechanical design

- High technological know-how

- Reliability and quality

- Cost-effectiveness

- OneStopShopping

- Flexible sollutions

- Customer-centric solutions

Production videos

Mechanical design

Mechanical design and product development are the first steps towards a finished product. Product development and design are guided by customer needs and views. Good product design can have a significant impact on product performance, quality and cost.

Levytekniikka has over twenty years of experience in mechanical design.

Tool lists for our Amada sheet metal working centers 10.01.2020 in PDF format:

STANDARD TOOLS

SPECIAL TOOLS

eDrawings Viewer for 3D models, DXF / DWG files.

LINK TO THE INSTALLATION PAGE

eDrawings Viewer for 3D models, DXF / DWG files.

LINK TO THE INSTALLATION PAGE

Products and manufacturing

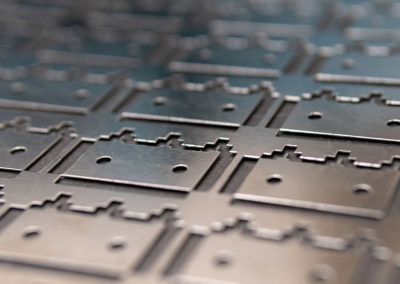

The pictures show examples of our products. We manufacture products and assemblies with material thicknesses of 0.4-20 mm. Materials include steel, stainless and acid proof steel, coated steels, aluminum, brass, copper, tin bronze, various spring steels, and polycarbonate.

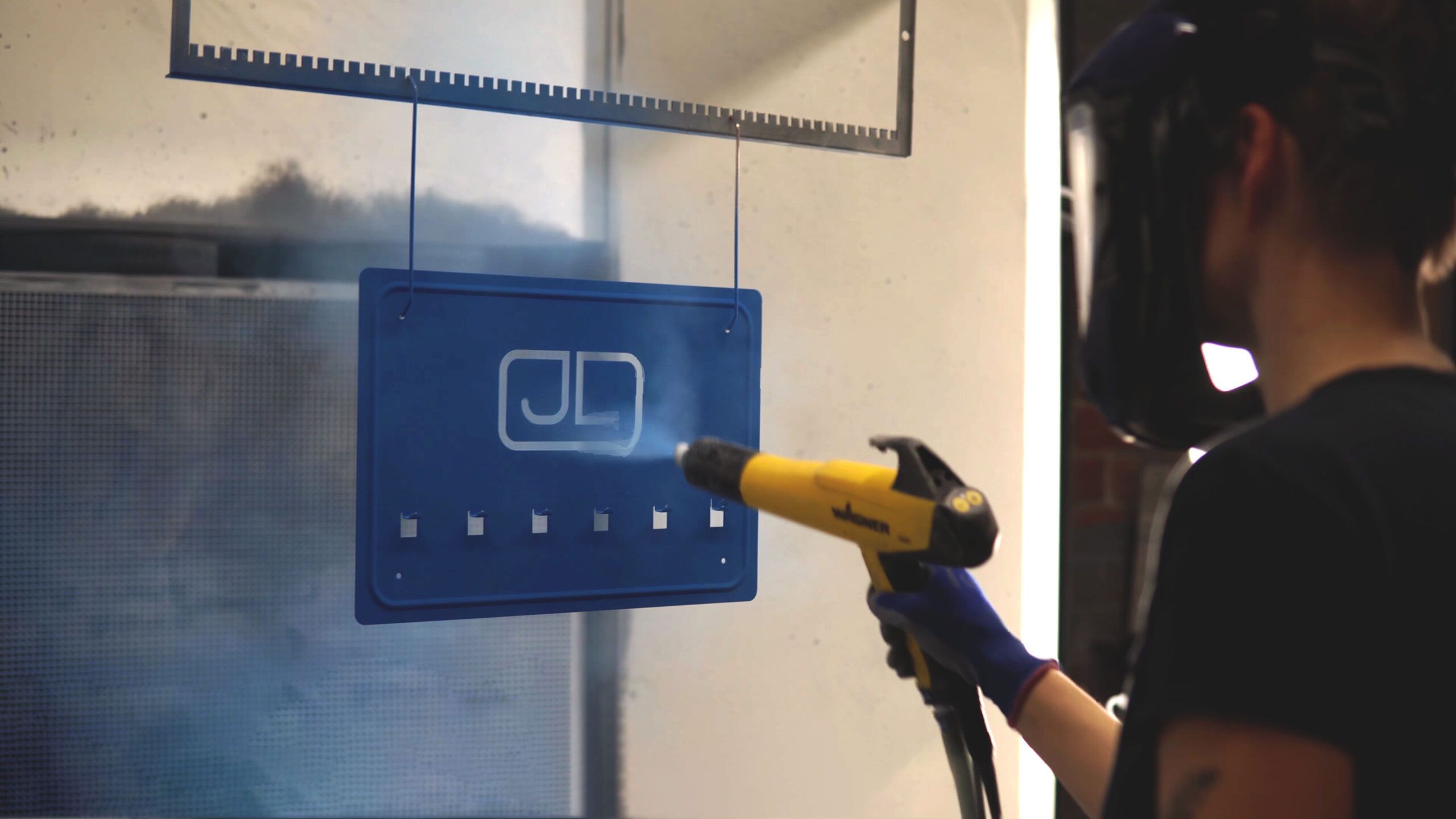

Powder coating

Powder paint gives a very hard, mechanical- and chemical resistant surface. The benefits are significant: inexpensive, eco-friendly, fast and durable coating.

There is also a wide range of specialty coatings available to create the necessary features for the products. Examples of special coatings are camouflage colour paintings AN11, AN44, AN100 and the including epoxy or polyester resin based zinc primer. AN-painting is often done using multilayer painting technique, which Levytekniikka has experience in.

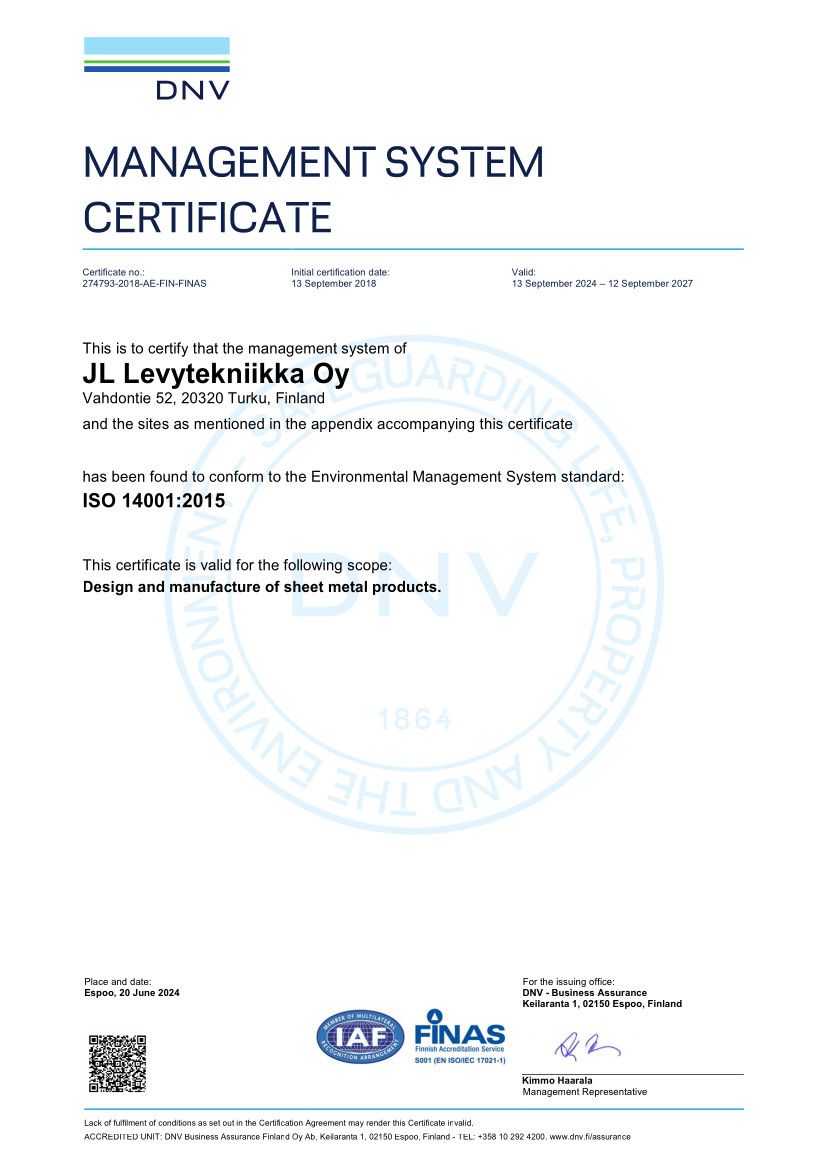

Quality and environment

Building a better tomorrow

JL Levytekniikka Oy’s goal is to take into account the environmental requirements in all its operations. Taking the environment into consideration is part of the company’s business. We are constantly developing processes and operations in an environmentally friendly way.

The quality of our operations is certified by the ISO 9001: 2015 quality certificate and the ISO 14001: 2015 environmental certificate.

We fulfill our packaging producer’s responsibility by being part of Rinki. Rinki and producer organizations organize the collection and recycling of carton, glass, metal, plastic and wood packaging. Our company also uses recycled pallets.

JL Levytekniikka Oy complies with the requirements of GDPR (General Data Protection Regulation).

We are committed to following the Code of Conduct in all aspects, including our internal operations. We also require our suppliers to follow the guidelines. The guidelines are also included in our quality and environmental manual.

The ability to track products is important for the reliable supply chain management. The entire supply chain of JL Levytekniikka is traceable from the end product to the origin of the raw materials.

Natural heat is a clear investment for the environment. The production facilities are heated using an environmentally friendly water-air heat pump (VILP).

Certificates

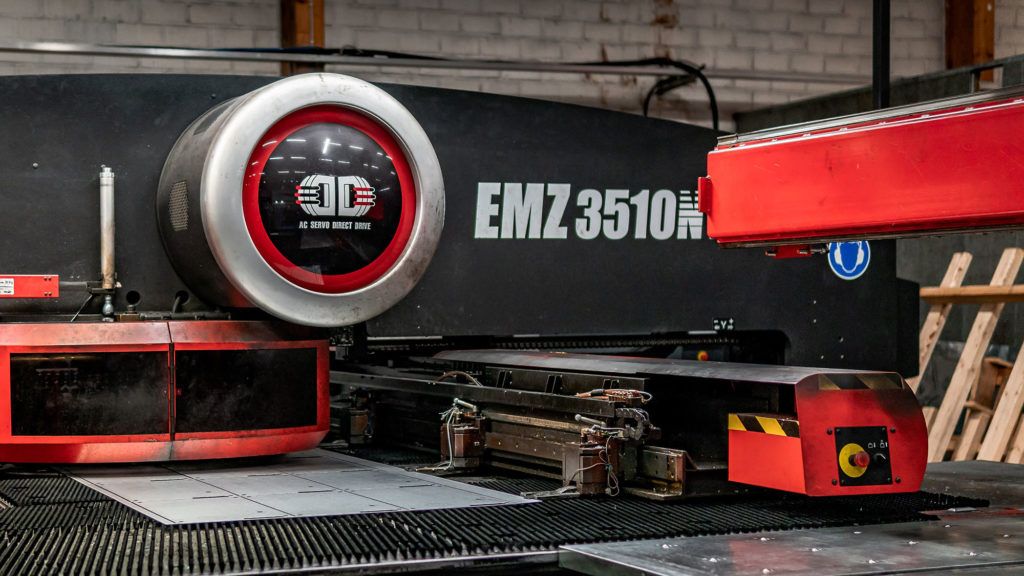

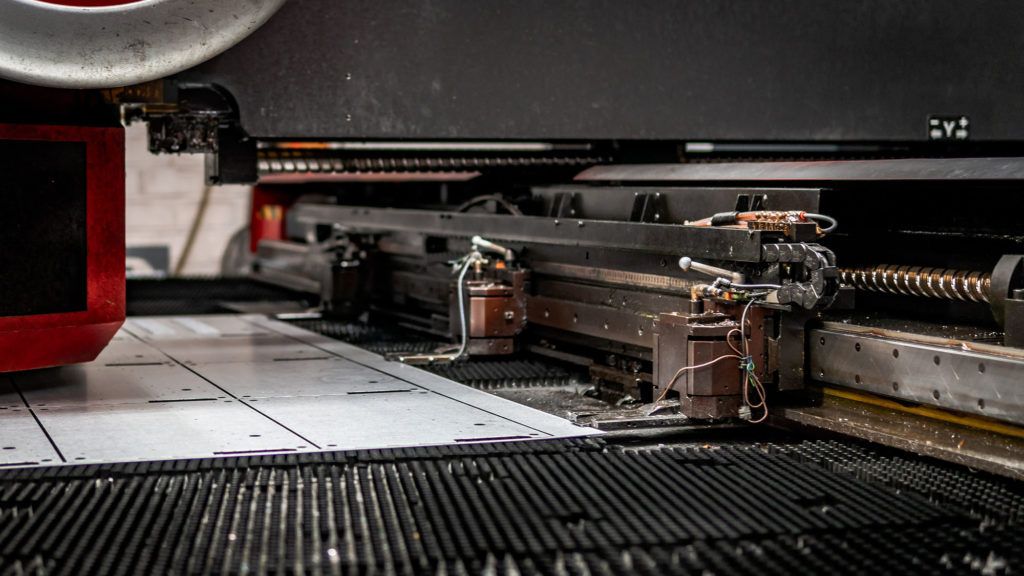

Production equipment

Our production equipment consists of modern and versatile machines and equipment. We invest in energy efficiency, minimization of environmental impacts, energy efficiency and automation.

We have four Amada sheet metal work centers. They can cut steel up to 4 mm and aluminum up to 5 mm. The maximum blank size is 1250×2500 mm. The machines also use threading units.

– 1 kpl EMZ 3510NT with LKI MP 250 charging and unloading robot.

– 1 kpl Vipros 358 King with LKI MP 250 charging and unloading robot.

– 1 kpl Pega 358 with LKI MP 250 charging and unloading robot.

– 1 kpl Europe 258 with LKI MP 250 charging and unloading robot.

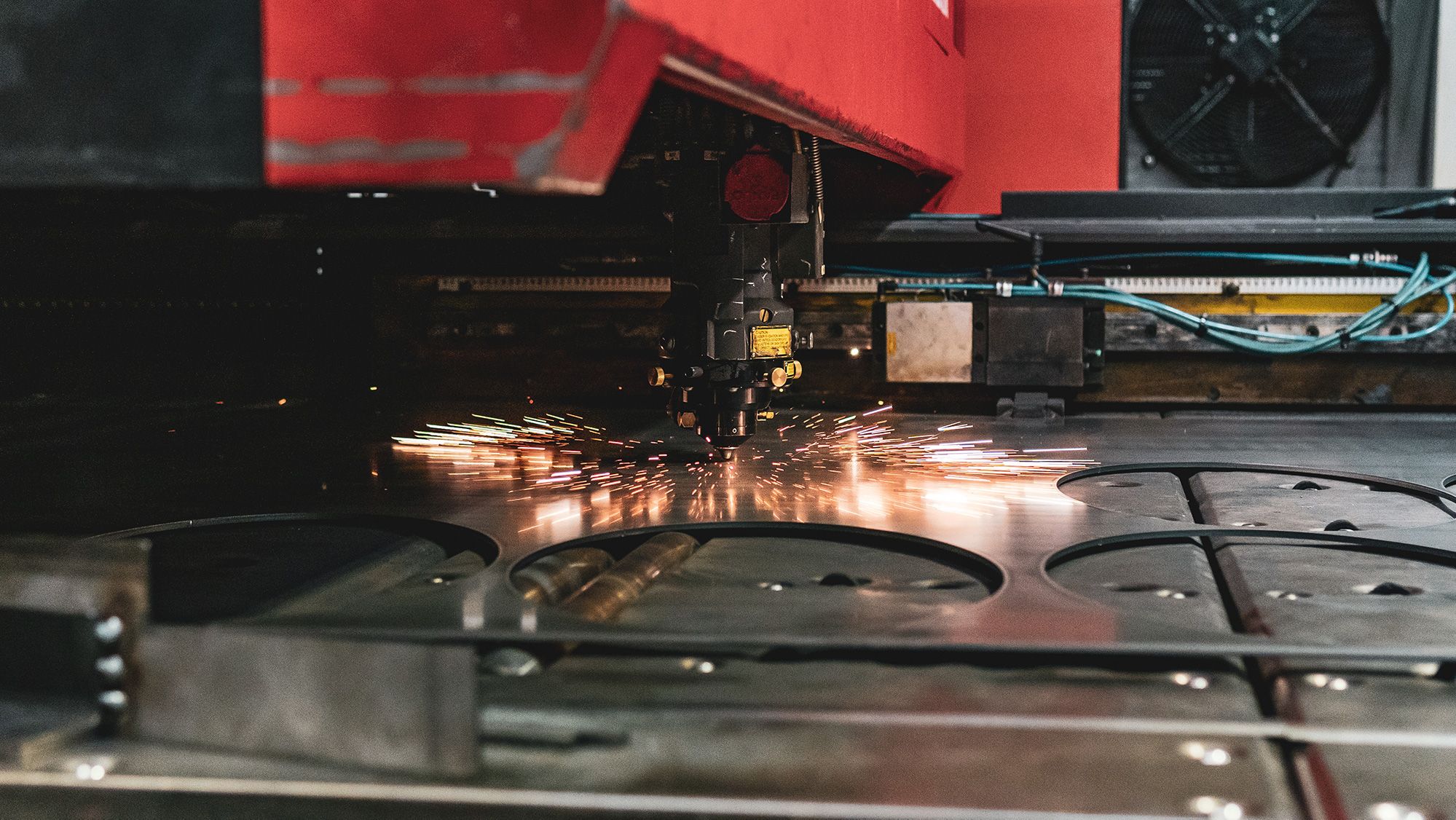

We use Amada’s Alpha 2415 4 kW – laser cutting machine line with robotic feeding and unloading stations. The machine can cut steel up to 12 mm, with a blank size of 1500×3000 mm.

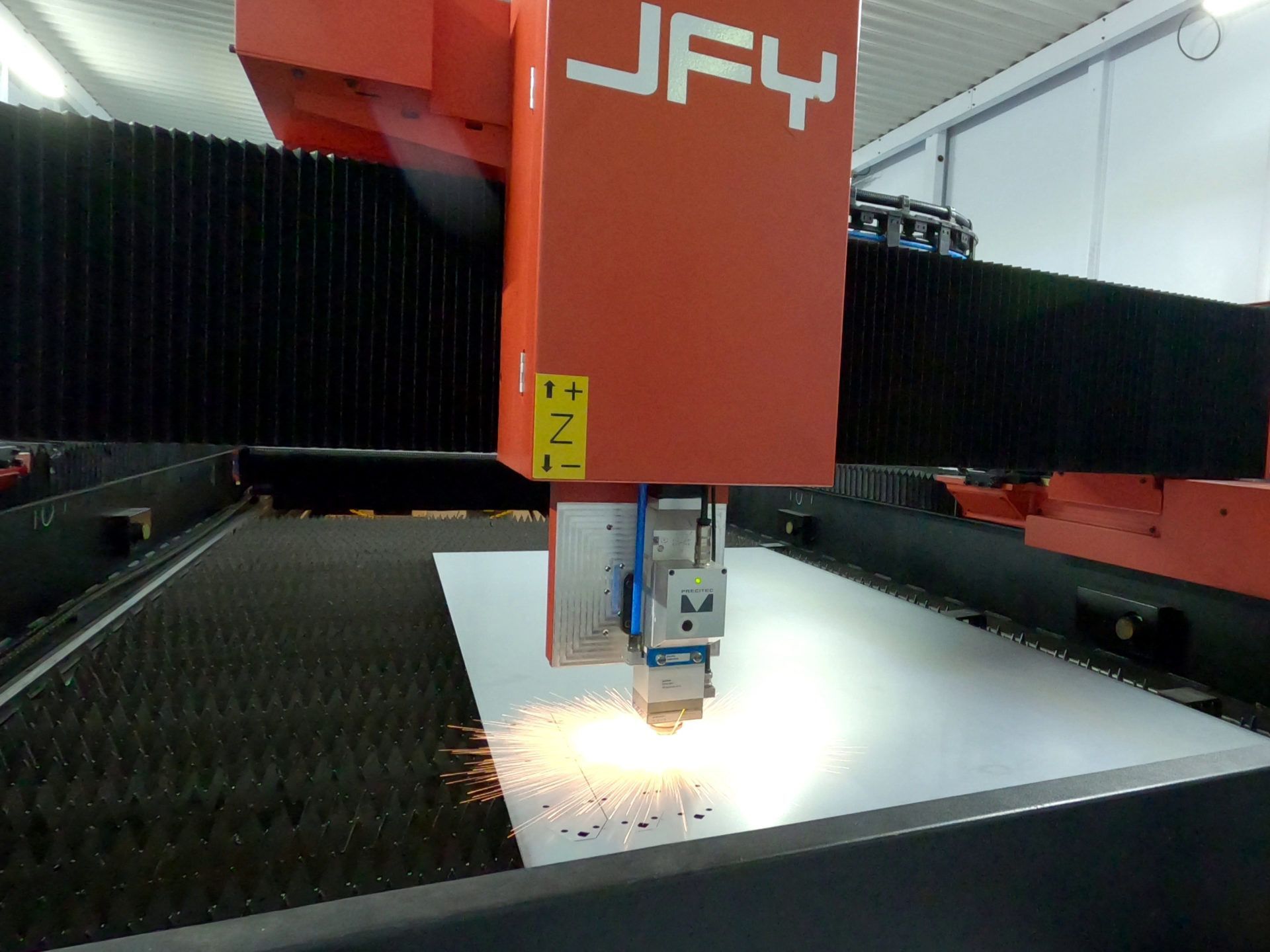

We also use a fast and efficient JFY EFC fiber laser equipped with a Trumpf TruFiber resonator, which can cut steel up to 20 mm.

Press brake line:

The line includes 12 press brakes, including HFE 3i and HRB from Amada’s latest generation. The maximum bending capacity is L = 3000 and F = 2250kN (225Tons).

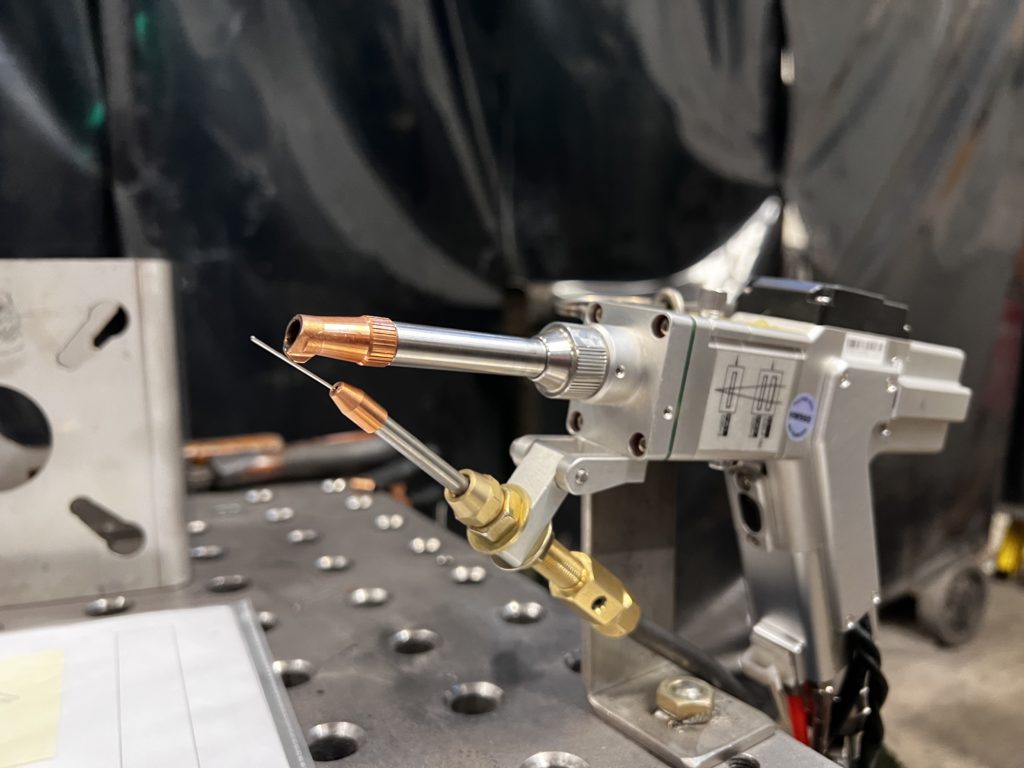

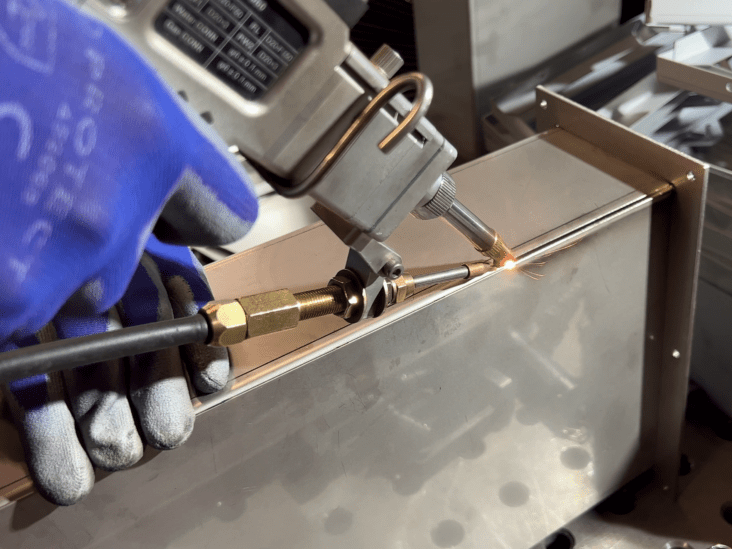

Laser welding:

Laser welding is suitable for sheet metal production. Welding of stainless steel, aluminum and alloy steels is cost-effective. The weld seam is visually good and durable. Thin materials do not “wave” thanks to the low heat output. We have 2 laser welding devices.

Other production equipment

– Four PEM-serter press machines with automatic feeder for fixing nuts, screws and sleeves.

In addition, TOX riveting for different materials.

– Three threading machines.

– Welding: 2 TIG and 3 MIG / MAG, as well as three spot welding machines.

– Riveting tools for mounting rivets and rivet nuts.

– Several modern riveting tools for the installation of rivets and rivet nuts. In addition, quick riveting tools for traction rivets, also as a drum feed.

– Quick cutting with presses (max 600kN)

– 2 lathes

– Amada disc cutter (2000 mm wide).

– Painting station with modern Wagner powder coating equipment.

Pretreated with nanoceramic adhesive coating and degreasing in chamber washer.

Company

JL Levytekniikka was established in 1994, to produce sheet metal parts and solutions. The company is owned by executive management.

History

1994

The business of JL Levytekniikka Oy started when the management at the time acquired the entire business from the Teleste Group together with Aboa Venture, a Turku-based private equity firm. The company continued its operations in Turku, premises leased from Teleste.

2000

Aboa Venture divested its shareholding and the entire share capital of the company was transferred to the management.

2001

Strong revenue growth and investments in automatic sheet processing, edging and powder coating required additional production space. The company moved to the border of Turku and Raisio, where we are still operating today.

2019

The acquisition of JL Levytekniikka was transferred to a new owner. In June, the board management acquired the entire share capital of the company. Operations in JL Levytekniikka continue as normal and are continuously developed to meet customer requirements and to remain competitive.

2023

Levytekniikka has expanded its operations by opening a new office in Raisio. Service for customers will continue as normal. Service development is done continuously for competitiveness, quality and delivery efficiency.

Contact

Contact us for more information about our services or request a quote. We’ll be happy to tell you more.

Send a message

JL LEVYTEKNIIKKA OY

Vahdontie 52

21280 RAISIO

The address for navigators, is Takametsäntie 2, 21280 Raisio

Tel +358 503871845

firstname.lastname@jl-levytekniikka.fi

Orders:

Request for quotation:

jose.palmeiro@jl-levytekniikka.fi

Billing information

VAT number: 09873860

Online invoice address: 003709873860

Broker identifier: OKOYFIHH

PDF invoices: ostot@jl-levytekniikka.fi

Mikko Kiviluoto

Managing Director

Timo Stenberg

Production Manager, quality

Puh +358 400 791610

Anne-Marie Stenberg

Procurement and Systems Development Specialist

Puh +358 40 869 7123

Jani Lönnblad

Supervisor

Puh +358 45 1285589

Jose Palmeiro

Sales Manager

Puh +358 45 278 7744

Matti Salminen

Mechanical design

Tel +358 503597562

Monika Österholm

Order processing and invoicing

Tel +358 503871845

E-mail: toimisto@jl-levytekniikka.fi

Miia Kiviluoto

Shipment and reception of goods

Tel +358 45 141 5656

E-mail: lahettamo@jl-levytekniikka.fi